- Shipping Company Estimated Delivery Time Shipping Cost

Highlights

Flsun V400 Delta 3D printer's main features

The Flsun V400 is an extremely user-friendly Delta 3D printer. The 3D printer features extremely fast printing speeds of up to 600 mm/s and an acceleration of 10 000 mm/s². This saves you more than 70% of the usual printing time while still producing high-quality 3D prints.

- Ø300 x 410 mm

- Printing speeds up to 600 mm/s

- Printing temperature up to 300 °C

- 7-inch LCD touchscreen

- Preinstalled Klipper firmware

- Direct drive extruder

- Dual linear rails

600mm/s High-Speed Printing, Klipper Firmware

Pre-installed full Klipper firmware (Klipper, Moonraker, Mainsail, KlipperScreen, WebCAM, etc.) brings FLSUN V400 a 600m/s high-speed printing effect with no configuration required.

The self-designed and developed all-metal frame structure, combined with the delta structure, is suitable for high-speed printing. With the same printing quality, the printing time can be saved by more than 70% compared with the mainstream 3D printer structure.

Ultralight Short-Range Extruder, Bi-Metal Construction

FLSUN V400 is designed with an ultra-light short-range extruder, which can meet the needs of high-speed printing of 600mm/s, especially suitable for printing flexible consumables and hard consumables such as PLA. The extruder throat tube adopts a bi-metal structure, which can meet the high-temperature printing of 300 degrees.

7-inch Wide-angle IPS

Using a 7-inch wide-angle IPS ultra-high-resolution interactive screen, the same multi-touch interaction scheme as Apple's mobile phone, and a newly optimized KlipperScreen interface, the FLSUN V400 3D printer's operation is more concise and convenient.

300x300x410mm Printing Size, High Precision

It can print objects with a maximum diameter of 300mm and a height of 410mm. Adopts a dual-axis wire gauge, the precision is higher during high-speed printing.

PEI Spring Steel Platform and 110 Celsius Hotbed

The separate magnetic PEI spring steel platform makes the first layer of printing more firmly bonded, and the model is easy to take.

The hotbed can be heated up to 110 Celsius, and various materials can be printed with appropriate setting parameters.

Filament Break Detection

Supports broken filament detection, automatically pauses after the normal use of consumables, and continues printing after replacing the consumables.

Auto Leveling

Self-developed leveling algorithm compensates the machining errors through 25 points, which can easily solve the first layer problem.

Fan Cooling System

Two dual ball fan cooling systems ensure the model cooling effect and fan life.

Specification

|

General |

Brand: FLSUN Type: 3D Printer Model: V400 Color: Black |

|

Specification |

Printing Size: 300x300x410mm (Highest Point) Molding Tech: FDM Nozzle Diameter: 0.4mm Layer Height: 0.05-0.3mm Precision: ±0.15mm Nozzle Type: Single Nozzle Environment Temperature: 5-40 Celsius Nozzle Temperature: ≤300 Celsius Hotbed Temperature: ≤110 Celsius Filament Support: PLA / PLA+ / ABS / PETG / WOOD / TPU / PC / NYLON (Need dried) Printing Speed: 600mm/s File Format: STL/OBJ/AMF/3DS Slice Software: Cura (recommend) / Simplify3D / prusaslicer / ideamaker File Format: G-code / UFP (Previewable model) Working Mode: Website / Flsun Speeder Pad Data Transfer: WiFi / USB Voltage: Input: AC 115V-230V, Output: DC 24V Power: 450W Leveling Type: Auto-level Filament Detection: Yes Extruder Type: Direct Extruder System: Flsun system 1.0 |

|

Weight & Size |

Product Weight: 17kg Package Weight: 20kg Product Size(L x W x H): 48x43.5x109cm Package Size(L x W x H): 103x46x19cm |

|

Package Contents |

1 x FLSUN V400 3D Printer 1 x User Manual |

Videos

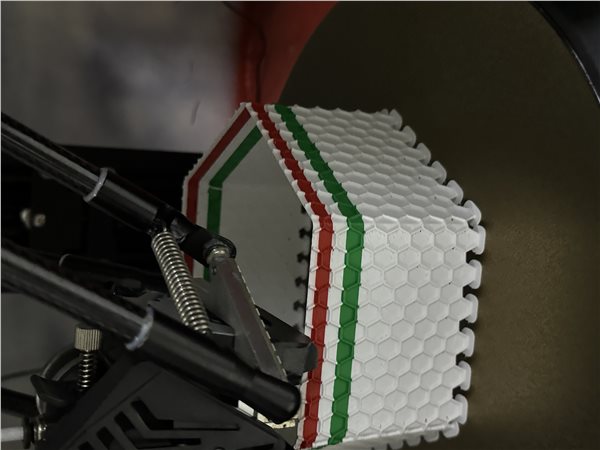

Customer Photos

Customer Videos

Customer Reviews

| 5 star | 148 | |

| 4 star | 5 | |

| 3 star | 0 | |

| 2 star | 0 | |

| 1 star | 0 |

- All (153)

- Images (18)

- Videos (1)

Questions & Answers

FAQ

1. What type of motherboard is used in V400?

The V400 uses the MKS nano v2.1 motherboard with Klipper firmware.

2. What is the type of driver used in the V400 and what is the range of current passing through it?

V400 using 2226 driver with 1.5-2A current.

3. What is the belt type and length and width of the V400?

V400 belt model GT2, width 10mm, single length 1458mm.

4. What are the nozzle types and available nozzle models for the V400?

The nozzle used in V400 is our own designed high melt nozzle, the profile size can be adapted to the crater nozzle, but the printing speed needs to be reduced when printing. v400 supports 0.2/0.3/0.5/0.6/0.8 caliber nozzle, but the configuration parameters in cura4.13 should be modified simultaneously.

5. What is the maximum temperature that the nozzle and hot bed of V400 can reach?

The nozzle can reach up to 300 degrees and the hot bed can reach up to 110 degrees.

6. How many ways are there to print on the V400? What are they?

There are 2 types of printing methods, namely U-disk printing and WEB-side printing

7. What kinds of print model file formats does the V400 support? What are they?

There are two formats, gcode format and ufp format (ufp format can show the model thumbnail).

8. What are the hot-side fan and motherboard fan models for the V400?

The hot-side cooling fan is 4010, the hot-side turbofan is 4510, and the motherboard cooling fan is 6015.

9. Are the V400's heating rod and temperature sensor the same as the SR's?

The V400 heating rod and temperature sensor use a longer wire than the SR heating rod and temperature sensor, and the V400 heating rod has a power of 60W, which heats up faster and warms up more.

10. How to check if the LOGO/LED light of V400 is not on?

Open the upper case of the machine, exchange the LOGO and LED jacks on the adapter board in the state of disconnection, turn on the machine, and turn on the LOGO/LED lights to see if they can light up and down normally. To determine whether the LOGO / LED light problems or adapter board problems.

11. The V400 machine can't connect to WiFi, what should I do?

1. After entering the wrong password, the network cannot be found. After reboot, you can delete and re-enter the password to connect.

2. It shows connected, but there is no IP address. The interface is: eth0 (network cable connection), you need to reboot the system to wlan0 (wireless connection), wait a while and the ip will appear.

3. There is an IP address, but the web side is inaccessible and shows an error. This indicates that the IP address has changed and you need to reboot to show the new ip.

Note: The connection must be made under the same LAN, after the PAD is successfully connected to WIFI, it will always be the same IP as long as the WIFI is constantly on.

12. What should I do if the nozzle hits the hotbed when the V400 is descending?

1. It may be caused by incorrect leveling steps, please re-level it.

2. It is possible that the configuration file is modified or damaged, please replace the original configuration file.

13. How to adjust the nozzle scraping model when printing?

1. Reduce the extrusion flow by ten percent

2. Replace the spiral icosahedron filling method

3. Properly reduce the printing (idle) speed

14. How to adjust the model does not stick to the hotbed?

1. Adjust Z0. If Z0 is too high, the model will not stick to the hot bed, and if Z0 is too low, the model will warp. (If the first layer has excess extrusion need to reduce the starting layer flow)

2. Properly increase the first layer printing temperature and hot bed temperature

3. Add skirt to the model

4. Apply solid glue to the platform

15. How to adjust the V400 machine with uneven adjustment?

1. First of all, make sure that the machine is installed firmly and without skew.

2. Make sure the order of leveling is correct

3. No impurities under the PEI board

4. No obvious resistance when sliding the slider, and keep the same tension of the three belts.

16. What should I do if the klipper has stopped on the V400pad page?

Whether this happens before or during printing, please open the web side of the machine on the computer page after connecting to WiFi to view the detailed error message. And send the error message to our after-sales service to solve it for you.